Premixed Air/Fuel in the PCC

CFD plus engine investigation of injecting a premixed air/fuel charge into an active pre‑combustion chamber on a large‑bore NG 2‑stroke engine. What improves, what regresses, and why. Experimental campaign is ongoing, this page only reports CFD process and results.

Project quick facts

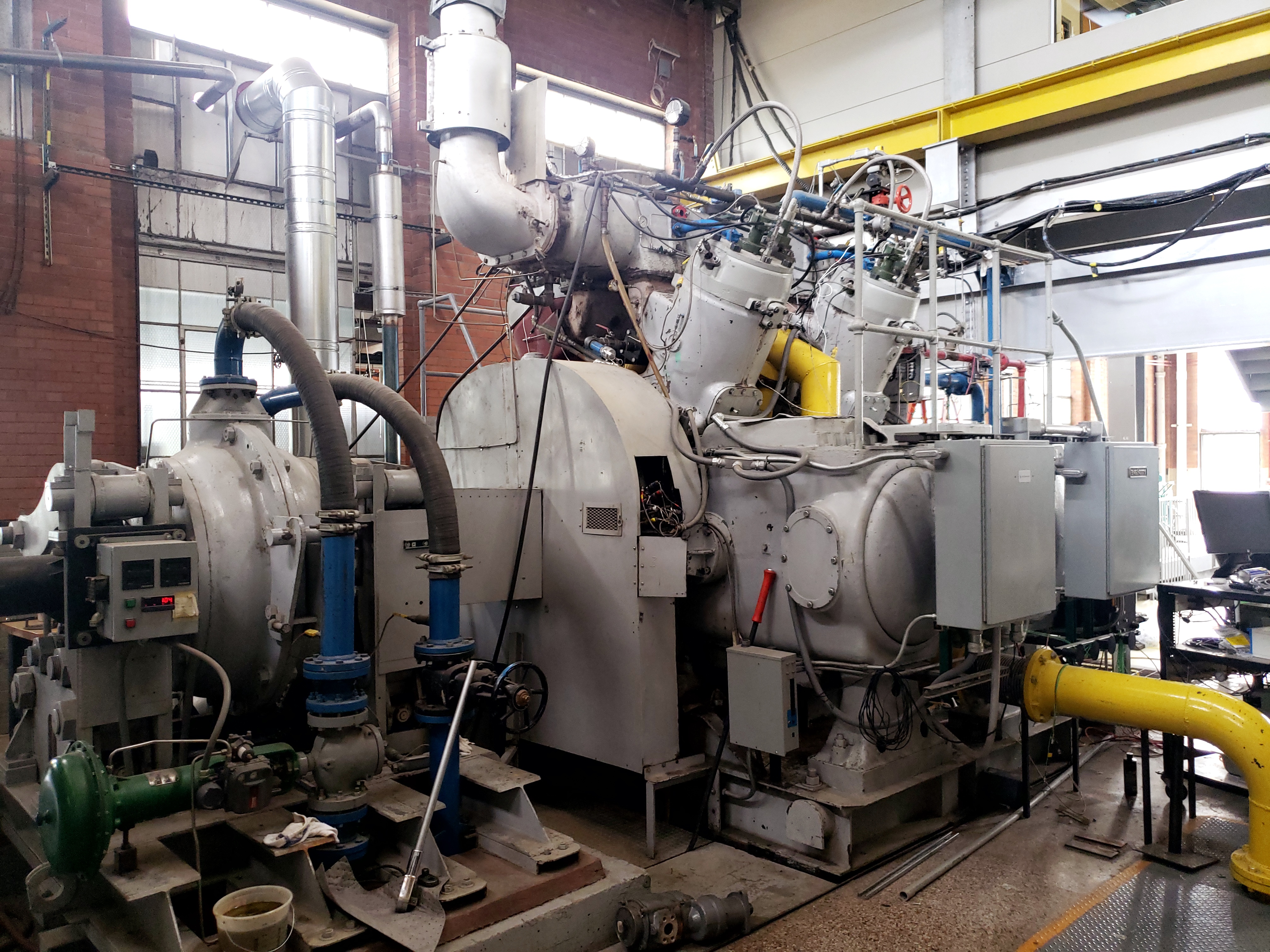

Engine platform

Cooper‑Bessemer GMV‑4TF • 2‑stroke LB NG • Active PCC

Methods

CFD and lab validation

Blend range

Ø=[1.5, 4, 7]

Outcome

Under tested setups, premixed PCC was not a viable retrofit

Overview

Problem

Lean‑burn LB NG engines target lower NOx via active PCC, but stratified PCC mixtures can hurt stability and methane emissions. Can premixing inside the PCC help?

Objective

Evaluate premixed air/fuel injection strategies into the PCC for homogeneity, ignition stability, emissions, and impact on MCC combustion.

Approach

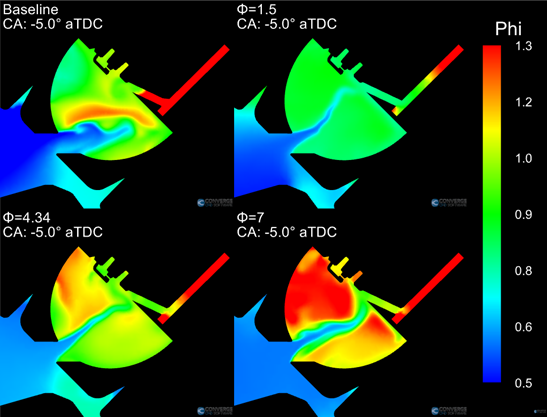

CFD setup

- Single‑cylinder GMV geometry; intake/exhaust modeled

- RANS k‑ε; SAGE combustion with detailed NOx

- Baseline calibrated to experimental trends

- Uniform “ideal premix” seeded at −6° aTDC for comparison

Premix strategies

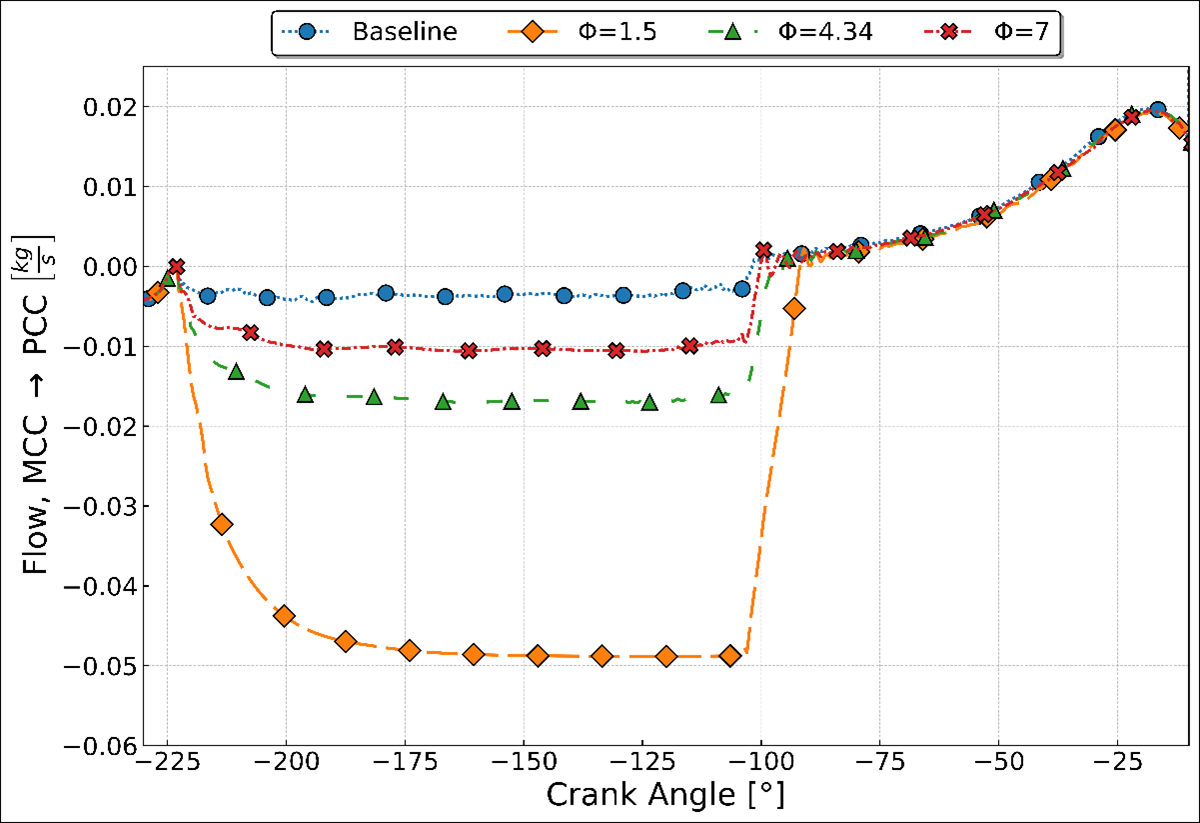

- Low‑pressure premix: PCC mass‑flow boundary; φ ≈ 1.5–7

- High‑pressure premix: pressure boundary ~150 psi; late SOI

- Tracked PCC/MCC φ, stratification (σ), TKE, MFB10/50/90, p‑θ, AHRR

Results & highlights

Ideal premix (uniform PCC)

- Lower ignition delay (faster kernel growth)

- Lower CH₄ & NOx residuals vs. baseline

- Slight power drop (peak pressure ↓ ~1.3%)

- Lean mixes need high mass flow → fuel pushed into MCC

- PCC homogeneity improves only for very lean injections

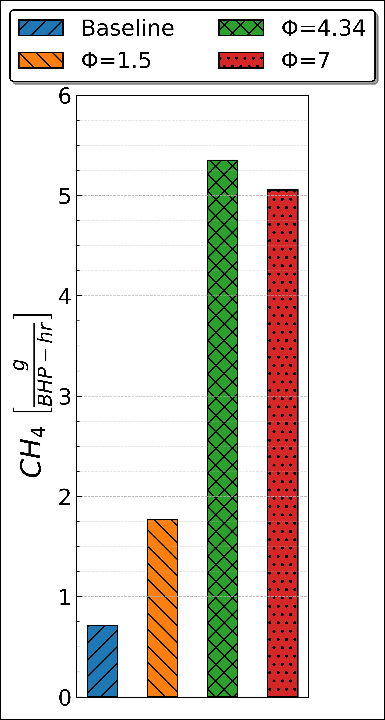

- Combustion weakens; power ↓; CH₄ ↑ markedly

- Later SOI reduces stratification but adds excessive turbulence

- Kernel cannot develop → misfires/very poor cycles

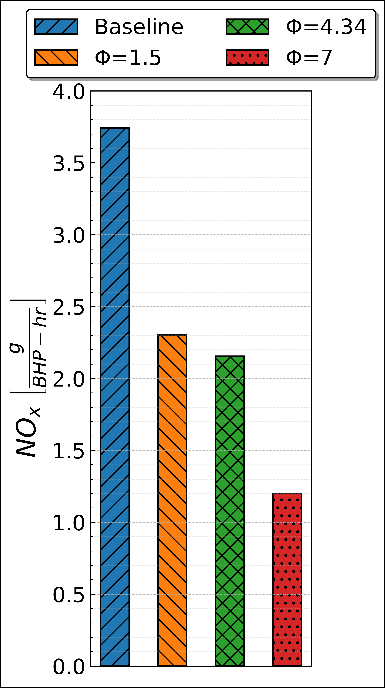

- Low‑pressure cases: CH₄ ↑ substantially; NOx ↓ from cooler cycles

- Overall power ↓ across premix cases

- Conclusion: premixed PCC not recommended as a retrofit